THE PROBLEM

The presence of micro-organisms in fuels has become one of the main problems directly affecting sectors such as industry, shipbuilding, petrochemicals and agriculture.

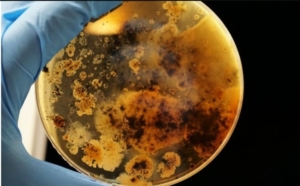

When studying the first signs of microbial growth inside storage tanks, it was observed that, firstly, they are contaminated by bacteria, fungi and yeasts that do not need light and are sometimes anaerobic. Secondly, their growth and proliferation increases exponentially in fuel tanks subjected to high relative humidity.

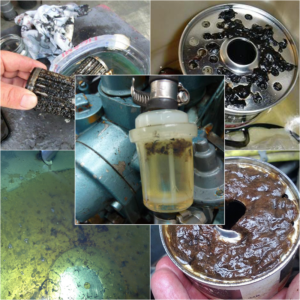

As the biological contamination of the fuel progresses, it disables all the systems on which it depends, causing the fuel container to corrode.

Nowadays, fuel storage tanks are normally manufactured in fibreglassbut there are also others made of rust-resistant materials such as steel, aluminium or pvc. However, since the problems caused by the use of fuels, service stations have been forced to use coatings made of composite and glass fibre reinforced materials, as they offer a higher resistance to aggressive media.

The tanks are made of FRP (fibreglass reinforced plastic).

The corrosion barrier of this class of tanks is constructed of polyester resin for the storage of fuels with alcohol blends ranging from 30% to 100%. These tanks are compatible with storage of materials such as petrol, diesel and petrol-alcohol mixtures, which generates biological wear on their surface, as well as biodegradation and biocontamination of the fuels. This is particularly serious on ships, where propulsion systems are critical and tanks are located in the hull of the ship itself.